Air Compressor Management System

Air compressors are referred to the machine used to compress air to increase air pressure. They are mainly used in steel, electric power, metallurgy, shipbuilding, textiles, electronics, chemicals, oil and gas, mining, light industry, machinery manufacturing, papermaking and printing, transportation facilities, and food industries. The fields of medicine, casting and spraying, marine terminal, military technology, automobile industry, aerospace, and infrastructure that provide power for different tools, transportation equipment, lifting equipment, and snatch gear have gradually become part of the Industrial Internet of Things. DFI's system-on-chip solution assists a famous air compressor manufacturer, who has a history of more than 100 years, enter the new field of the Internet of Everything.

Region: United States

Industry: Industrial-grade Air Compressor

Application: Air Compressor Management System, IoT gateway

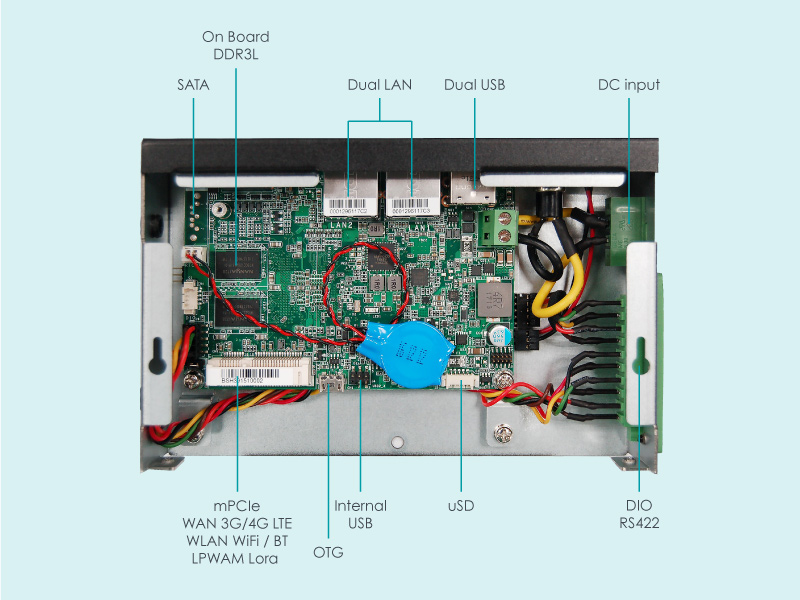

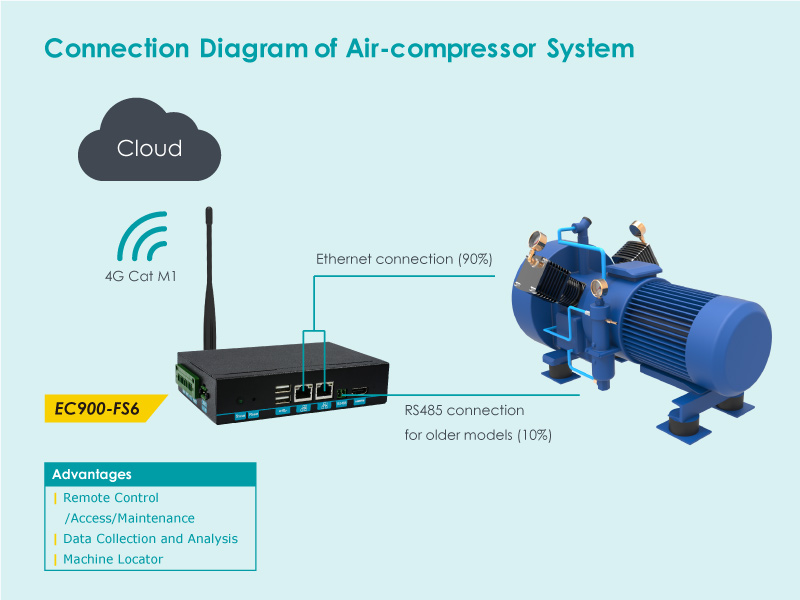

Solution: EC900-FS6 (NXP i.MX6 system-on-chip)

An air compressor is a machine that compresses the air and increases air pressure at the same time. It has a wide range of applications. The typical application areas include HVAC (Heating, Ventilation, and Air Conditioning), refrigeration cycle, industrial power, silicon chemical industry, petrochemical, natural gas transportation, and etc., which can be described as ubiquitous. With the development of information technology and the popularization of the industrial Internet of Things, air compressor manufacturers in seemingly traditional industries must also digitize and manage tasks remotely while introducing more advanced data analysis to reduce sophisticated air compressors' maintenance costs.

In the past, if the air compressor needed to be repaired, it was necessary to send someone to the site to confirm the problem and then bring the materials and parts back for repair. If there are materials and components in the maintenance vehicle, it can be completed at one time. If not, you must run a second time, wasting workforce and material resources. In past application scenarios, the supplier does not know the air compressor's actual installation location. However, with a wireless network (such as a low-power IoT wireless network or GPS built-in LTE module), the supplier can know the operating system’s status and location, which helps with business decisions. Because of this, a large air compressor factory in the United States with a history of more than 100 years introduced a remote management system to effectively monitor the operating status of the air compressor, collect operating records, and detect problems in advance to predict the maintenance cycle. The deployment environment sends data to the cloud-based management center through wireless networks of different specifications. But the demand is not simple.

,有助於車隊管理員管理駕駛行為、運動感測、急煞車和衝擊偵測.jpg?timestamp=1689918406.42007)