Automated Guided Vehicle

The printed circuit board (PCB) is the primary material of electronic products and an indispensable part of all electronic products. EC70A-SU designed for solutions with limited space and high-performance requirements has various industrial-grade I/O interfaces to cope with multiple industrial control applications to improve the storage efficiency of the world-class printed circuit board manufacturers.

Region: Taiwan

Industry: Printed Circuit Board

Application: Automated Guided Vehicle

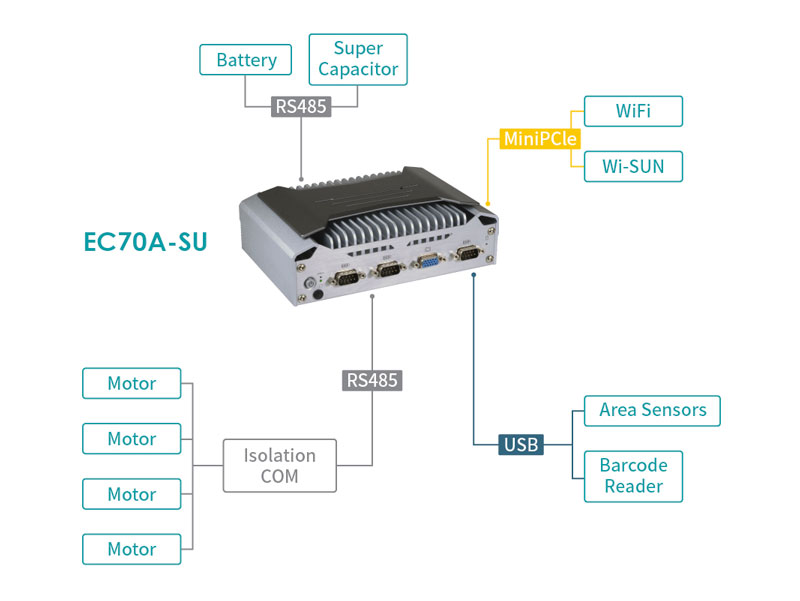

Solution: EC70A-SU

Automated Guided Vehicle (AGV) are commonly used in different industrial fields from warehousing to logistics and to highly automated smart factories. They can be seen everywhere. In moving towards intelligence, many Taiwanese companies hold a global leadership position in specific industrial fields. In line with the government's industrial technology policy, they are fully upgrading their manufacturing equipment to increase high-end products' production capacity, thereby increasing industrial competitiveness.

A Taiwanese electronic printed circuit board manufacturer ranked amongst the top five has fully introduced automated guided vehicles. Due to the characteristics of the production line environment, a more compact car body is required; it has rigorous space limitations and ambient temperature restrictions for its computing brain. Also, due to the vibration of loading and unloading items, more anti-shock reliability is needed. The internal structure requires six sets of COM ports for connecting mechanical components, compatible with protocols such as RS-232/422/485, and must have galvanic isolation protection. Finally, to improve indoor positioning, it is essential not only to have WiFi scalability but also to incorporate Wi-SUN for achieving more precise.

,有助於車隊管理員管理駕駛行為、運動感測、急煞車和衝擊偵測.jpg?timestamp=1689918406.42007)