Drilling Automation System

From automobiles to food to clothing, automation technology has disrupted many industries. The energy industry, which is highly dependent on large-scale oil drilling and oil well maintenance equipment, has been incredibly beneficial. The essential tools for laborers in oil and gas drilling projects are not a toolbox full of wrenches and pipe benders, but laptops, computers, and a drilling automation system for "Transforming a Vision into Reality." In Russia, where the economy is hugely dependent on oil and gas exports, DFI has made BT9A3-T20-E27 the reliable brain of the drilling automation system after long-term testing and validation with its trustworthy product quality and meticulous customer service.

Region: Russia

Industry: Petroleum

Application: Drilling Automation System

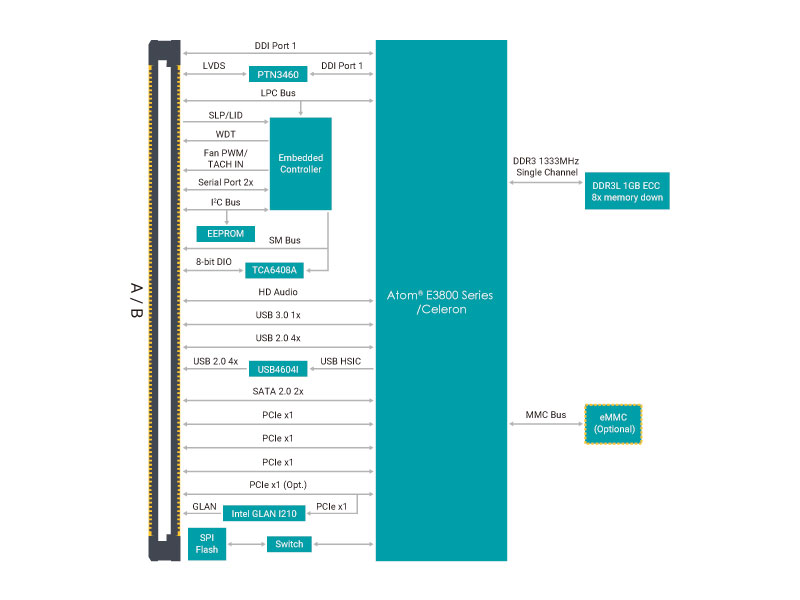

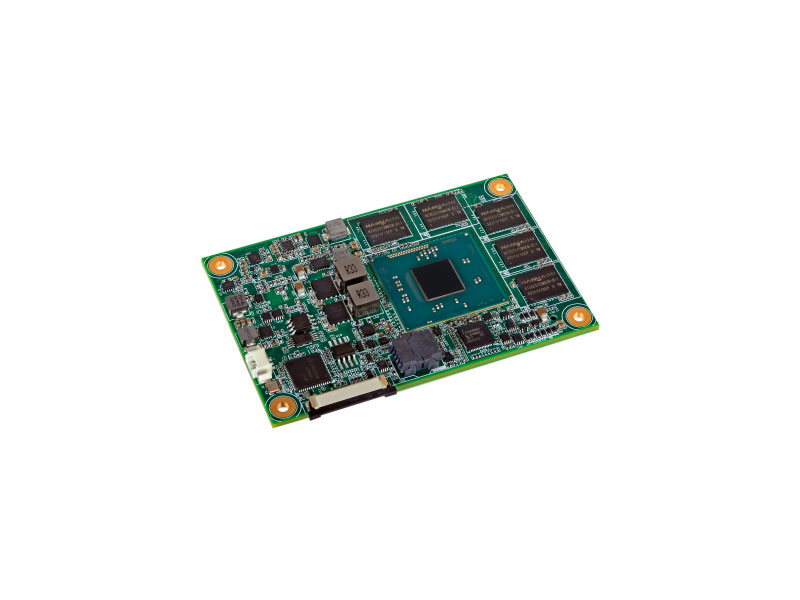

Solution: BT9A3-T20-E27

Oil and gas drilling is a great project that grabs resources from the Earth. Drilling success rate, operation efficiency, and cost control profoundly influence the success or failure of oil and gas exploration, production investment, and operating performance. For Russia, where oil and natural gas account for about 40% of the country's total income, it is even more crucial.

Drilling is a hazardous operation, which often suffers from the abnormal pressure of the formation, the blowout of oil and gas, and toxic gases. To detect hazards in advance and take appropriate steps, monitoring systems are often set up and, with the aid of instruments and equipment can feel the feedback from the ground and adjust the construction steps. The monitoring system includes the measurement of drilling parameters, such as weight, speed, torque, drilling rate, pressure, depth, brushing, extrusion, etc. Also, the mud circulation system monitors activities such as mud specific gravity, temperature, volume, pump stroke number, circulation time, rotation speed, spray speed, etc., as well as monitoring of oil and gas characteristics such as natural gas, crude oil, toxic gases, and trace elements.

,有助於車隊管理員管理駕駛行為、運動感測、急煞車和衝擊偵測.jpg?timestamp=1689918406.42007)