Multinational Service Capabilities In Response To Global Acquisitions

Globalization has accelerated multinational companies' integration to prompt companies to have their bases worldwide and conduct around-the-clock operations. At this moment, ODM manufacturers have global service sites, which is a must requirement.

From Denmark's world-renowned AMR manufacturer, parcel lockers throughout Europe, America, and Japan, digital signage deployed in major European airports, polypropylene film packaging label production equipment in the United Kingdom, drilling automation systems of Russian oil companies, Turkey highway vehicle monitoring, Norway's maritime monitoring system, American industrial-grade air compressors, Japanese air-conditioning manufacturers' centralized air-conditioning management systems, China's X-ray food and foreign body safety inspections, to Dutch police car dispatch systems, are the proven records created by all DFI's meticulous customer service and uncompromising product quality.

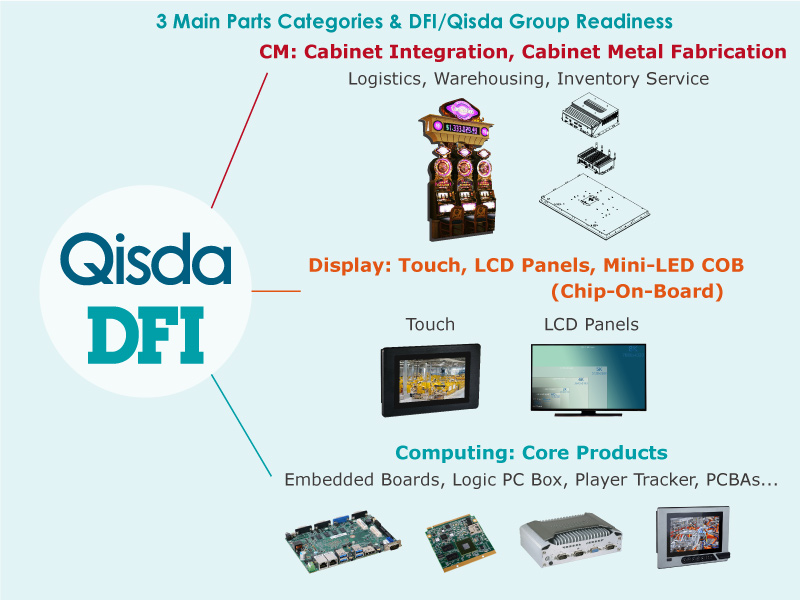

Flexible Production Bases and CKD/SKD Capability For Deployment Of Gaming Console

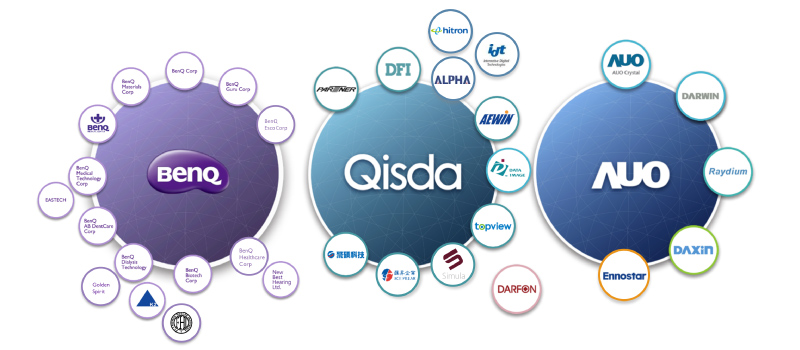

Qisda Group's manufacturing bases are located in China and Taiwan, with high-quality and flexible global manufacturing capabilities and diversified services such as economical-scale manufacturing or small quantities and diversification, which can meet customers' global or local supply needs. But it's far more than that.

In recent years many developing countries, led by the BRIC (Brazil, Russia, India, and China), have become emerging markets where aggressive strategists compete. To stimulate employment, job opportunities and protect domestic industries, these economies have adopted high import tariff policies on finished products that encourage local production, such as the semi-finished product assembly (SKD, Semi-Knock Down) and the bulk material assembly (CKD, Completely Knock Down), from SMT/DIP operations to PCBA.

Therefore, in a foreign country far away from Taiwan, building localized product manufacturing has become difficult. From product design, material management, transportation logistics, quality control, packaging, testing, and production line adjustments, even local parts procurement and rebuilding the part number system, each stage has been full of challenges and unknown risks.

Amongst them, the CKD has more stringent engineering and technical requirements than SKD. The vendor must execute the SMT/DIP of PCBA in the importing country. Therefore, appropriate manufacturing and testing equipment, corresponding and trained technicians to prepare operators, and strict supervision must be made during the entire process. Otherwise, it will be a challenge to achieve the domestic production line's exact yield and quality. The long-distance, the difficulty of the jet lag, and the language barrier vigorously test the R&D energy, service quality, and logistics ability.

These vast markets that impose heavy taxes on imported finished products are undoubtedly unattractive. Still, for many Taiwanese manufacturers that lack a local supply chain in these countries, it is an unattainable wall that discourages those interested in developing in these markets. With DFI's past achievements in these markets, such as the CKD projects of lottery machines in these countries, it is proven that DFI is enough to become the best ODM partner to meet all the needs of the global gaming industry.

,有助於車隊管理員管理駕駛行為、運動感測、急煞車和衝擊偵測.jpg?timestamp=1689918406.42007)