Automated Fabric Inspection

With the advancement of science and technology, the ancient textile industry has already entered the era of highly automated production. Even with the price challenge of many consumer-grade products, DFI has helped a European company that was established in 1927 and known for their excellent quality trusted by customers, by high flexibility paired with quick cooperation with customers to launch derivative products and long-term supply that industrial computer manufacturers could provide. In addition, customers who started operating auxiliary machines in textile factories and established quality standards for the textile industry for a long time created online fabric inspectors to allow existing automated textile machines to have automated quality inspections.

Region: Europe

Industry: Textile Industry

Application: Automated Fabric Inspection

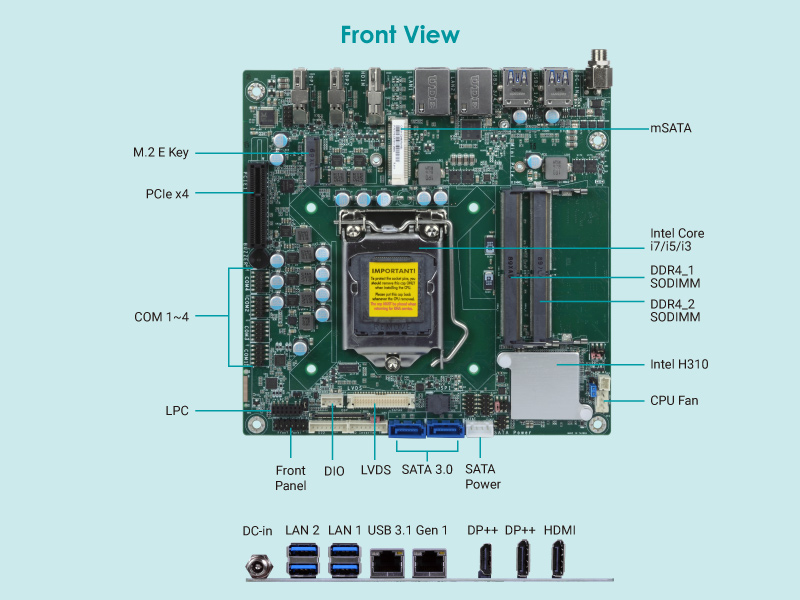

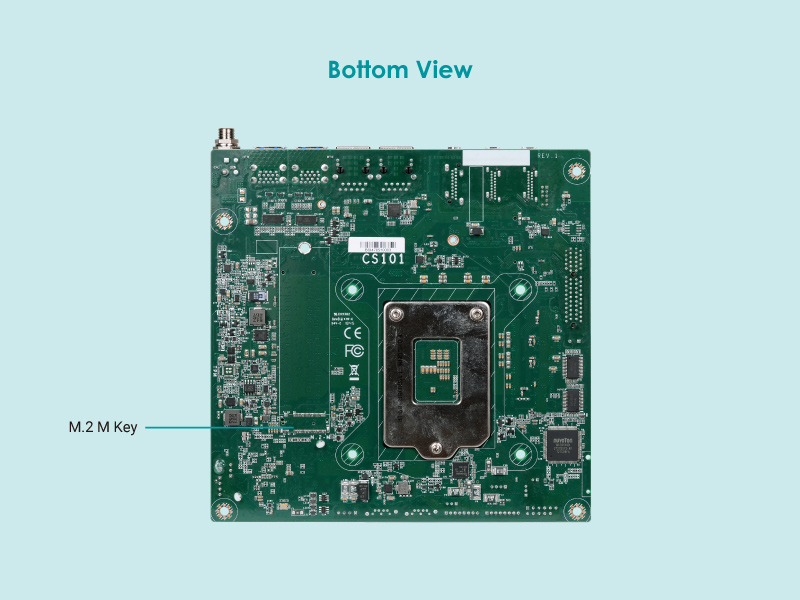

Solution: CS101-H310 Derivative

The textile industry refers to the design and manufacture of yarn, cloth, and clothing. It is an ancient industry that has been born since the beginning of human civilization. It is known that the earliest origin of textiles is the bone needles found on the site of the cave in the Paleolithic period in China, much earlier than the time of pottery. Hemp rope, linen, and other first textile hemp fabrics manufactured by humankind can be traced back to Egyptian linen fabric in 4000 BC and hemp fabric unearthed in Caoxie Mountain, Jiangsu, China, in 3600 BC.

Since the textile industry is inseparable from human life, it is also undergoing technological upgrades with industrial automation. Take the automobile industry as an example, "zero defect" has become a mandatory requirement. Applications such as airbags, roofs, vehicle interiors, tires, etc., require 100% perfect quality. Therefore, the textile industry is also inevitable. In today's production environment, high-quality automated solutions are the top priority for fabric quality testing.

Belonging to one of the Japanese multinational automotive manufacturers in the world, a specific European customer, that was founded in 1875 and begun operating auxiliary machinery for textile factories in 1927 and established textile quality standards since 1957, has launched a series of fabric inspection solutions for the entire value chain from weaving to finishing.

,有助於車隊管理員管理駕駛行為、運動感測、急煞車和衝擊偵測.jpg?timestamp=1689918406.42007)