Mail Order Fulfillment and Ecommerce Packaging Machine

DFI's customized touch panel PC has an intuitive interface with a touch panel access to operator tutorials, help system, on-board diagnostics, data retrieval, and performance monitoring with graphic or text-based views. This ensures accuracy and efficiency in fulfillment applications that require frequent product and label changes, prevents product queuing, and improves packaging operators' efficiency.

Region: United States

Industry: Automatic packaging

Application: Mail Order Fulfillment and Ecommerce Packaging Machine

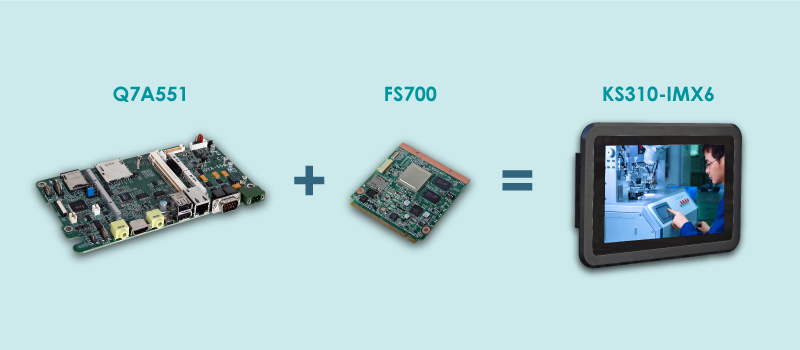

Solution: Customized 10.1” Touch Panel PC (NXP i.MX6 system-on-chip)

Automatic packaging machines are an industry with a long history. However, in recent years, due to the rapid popularization of e-commerce and mail-order distribution and the demand for customized packaging, packaging operations need to exceed the previous efficiency, such as the direct integration of thermal transfer imprinter.

From single or multi-line mail order fulfillment, e-commerce fulfillment, prescription-by-mail fulfillment, apparel, fashion accessories, sporting goods, footwear to a variety of products, the efficiency of automatic packaging machines has always played a pivotal role in logistics.

Modern automatic packaging machines feature a breakthrough bag opening technology that securely grips and holds the open bag in place. This creates a large, square opening that allows for effortless loading of single or multi-line orders. In addition, next-bag-out printing is achieved with an advanced thermal transfer imprinter positioned directly over the next bag to be loaded. This ensures accuracy and efficiency in fulfillment applications that require frequent product and label changeovers and prevents product queuing.

,有助於車隊管理員管理駕駛行為、運動感測、急煞車和衝擊偵測.jpg?timestamp=1689918406.42007)