人力消耗戰:體溫測量及維安把關

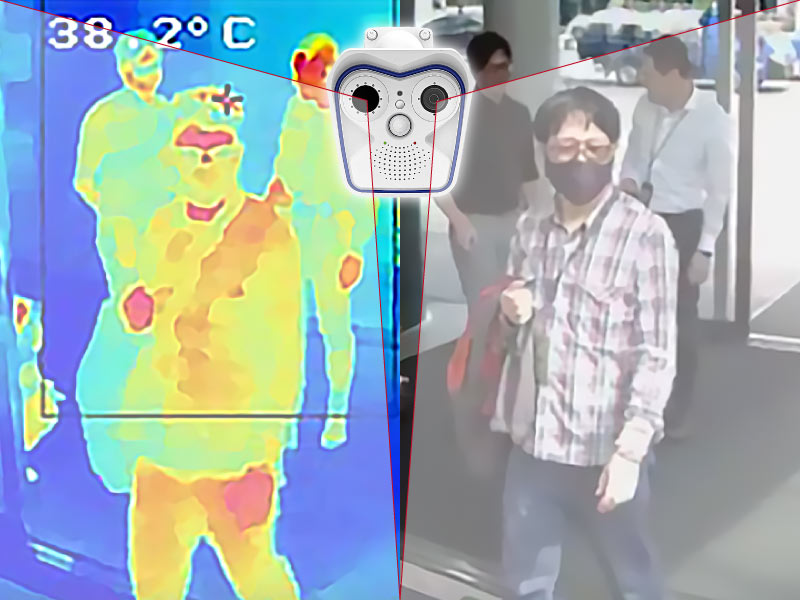

COVID-19的防疫抗戰,促使了檢疫設備的需求大增,同時更多人力也被迫投入在出入口的體溫量測。為解決此困境,DFI近期推出「全方位智慧熱感防疫系統」,智慧化多入口檢測與門禁,大量人員出入也不費額外人力。

We have noticed that you are visiting from North American areas. Would you like to browse the US site (US.DFI.com) for a better experience?

感謝您填寫這份問卷。 您的反饋將有助於改進我們的網站,並提供更好的用戶體驗。

非常不滿意

不滿意

普通

滿意

非常滿意

COVID-19的防疫抗戰,促使了檢疫設備的需求大增,同時更多人力也被迫投入在出入口的體溫量測。為解決此困境,DFI近期推出「全方位智慧熱感防疫系統」,智慧化多入口檢測與門禁,大量人員出入也不費額外人力。

針對大型場所如機場、各大車站的多點出入監測,DFI主打高規方案,只需單台攝影機,即可支援多區同步偵測與各區體溫顯示,大大提升辨識的效率、確保人流順暢不壅塞。

藉由熱感、IP二合一的攝影機,在疑似發燒者經過時,系統能直接擷取熱感與實際畫面、標記溫度、並即時通報監控人員前往處理。結合人臉辨識系統及資料庫的建立,更能使後續追蹤 疑似感染者效率大增。

此系統未來將結合各項科技、支援全方位應用,例如維安監控的人臉辨識,發展為完整的安全防護網,不僅能解決短期內的防疫需求,更是接軌智慧城市舉足輕重的一步。

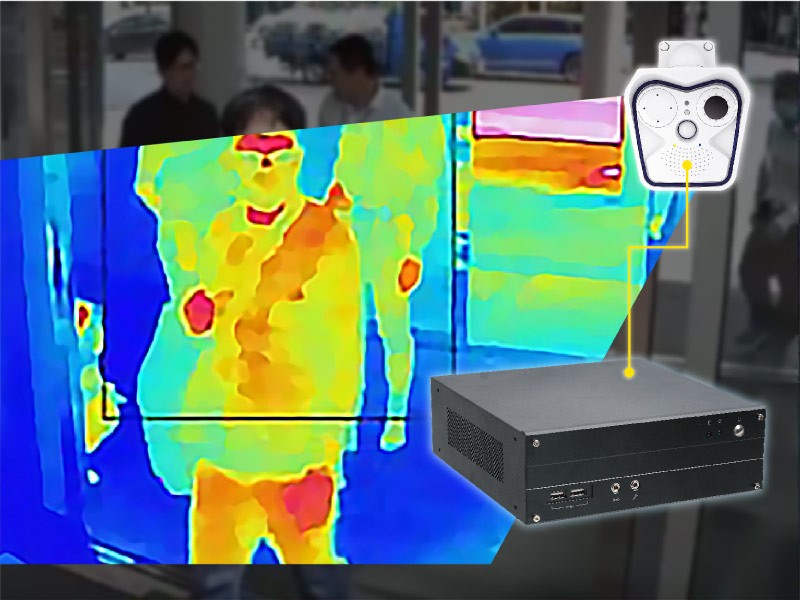

「全方位智慧熱感防疫系統」透過軟硬體整合,結合DFI的高效能IPC 及艾陽科技的訊號擷取技術,可以直接控制門禁,封鎖電子閘門、拒絕出入、並將發燒人員隔離在外。

如需了解更多次方案的詳細資料,歡迎下載相關文件。

相關文件

下載相關文件

使用者手冊

下載 iMage-E 使用者手冊

下載 iMage-M 使用者手冊

下載 iMage-F 使用者手冊

傳統工廠設計的生產單元大多只提供單一用途,而仰賴的額外處理作業也逐漸遭自動化淘汰。只有針對附加服務打造最佳化運算核心,才能讓收益率達到未來 AIoT 的水準,而且並不一定要將工廠完全換新。DFI AIoT 解決方案的主要目標之一,便是採用智慧工廠最新的運算平台及軟體技術,同時讓舊有生產線維持不變,協助您事半功倍。

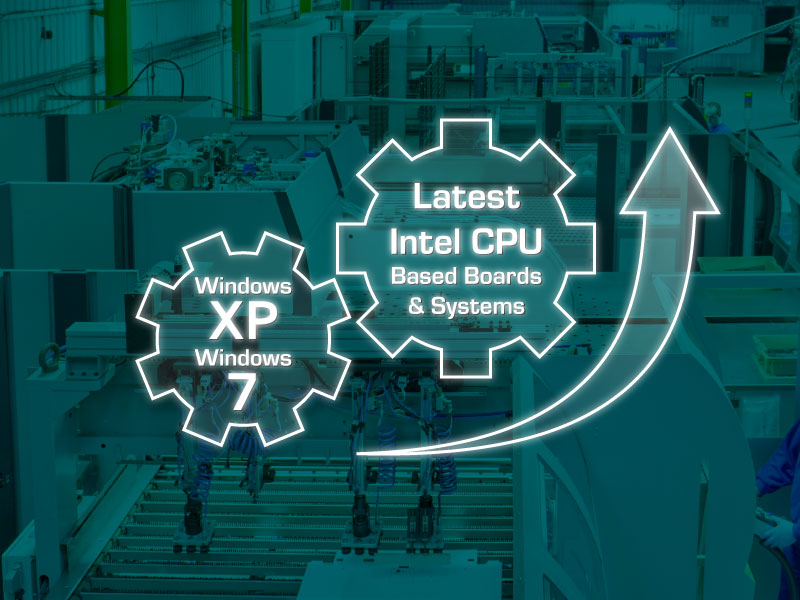

工廠需要升級並不是因為機器老舊,而是因為更新的 IPC、作業系統環境及軟體整合缺乏向下相容性。為了相容性向上升級確實值得考慮,但也可以有其他選擇。DFI 的 IPC 更新計畫結合 Intel Hypervisor,確保順利移轉所有舊有配置及資料處理流程,搭配舊有的設備及最新嵌入式運算處理器,AIoT也可以順利運行,從上到下實作各種自動化流程,進一步優化製造的成效。

生產線上的多台機器由於實體分離,其故障率可能大幅提升,且這些機器是以獨立的 OS 環境為基礎,因此各個機器可能需要自己的 IPC,導致濫用同步及維護作業。DFI 具備卓越的運算技術,可利用 ACRN™ Hypervisor Vmware 技術將所有平台整合為單一實體 IPC。其中將資源分為多個區域,讓不同 OS 平台能在單一 IPC 進行模擬,同時處理多項作業,例如 RTOS 的 Robot ARM、Windows 的 HMI,以及 Linux 的 AOI。

以機器視覺技術為基礎的臉部辨識、物體偵測及品質驗證,並不是純粹仰賴 CPU 及 GPU 等硬體運算能力,也需要與機器學習機制整合。傳統 IPC 架構無法在未來的 AI 環境中,因應機器學習的大量需求,不過在 Intel OpenVINO™ 深度學習最佳化工具上市之後,情況就大不相同。這套工具組使用經過訓練的模型,優化硬體的執行能力,與不同應用程式的特定架構同步,加速電腦學習急速成長。

DFI 秉持與 Intel 相同的願景,預見 AIoT 及 AI 的普及性,專注於提供全方位解決方案。高階工廠智慧化已是未來勢不可擋的發展趨勢,因此藉著更新IPC 及Intel 最新處理器,將成為未來智慧工廠成功的基石。

智慧預知維護 (Intelligent Predictive Maintenance) 可分析感測器收集的各項資料,例如震動、聲音及溫度測量結果,協調所有生產線的即時狀況。完整的工學統計資料也用於自動檢測,大幅提升維護作業的成效及效率,取代錯誤百出的目視/儀器檢測。

透過智慧演算法,記錄設備各種狀態的波動,儘早預測維修時機、排程維護時間,並透過深度學習及指示性分析深入計算評估庫存管理。預先的準備能避免突然停機、延長使用壽命,並減少停機時間和整體費用。

揮別昂貴的線上測量機器!自動化虛擬計量 (Automatic Virtual Metrology, AVM) 系統能在生產的同時進行自動微調。AVM 演算法仰賴感測器資料產生各個計量值的基準,動態微調達到極高的精准度。這套系統將延遲的離線隨機檢測,轉變為即時線上全面檢測,讓智慧預知維護成為符合經濟效益的品保替代方案,對半導體、面板和工具機等等只能使用離線檢測的產業來說,可是一大福音。

有別於在每條生產線都部署一台測量機器的傳統檢測方式,自動化虛擬計量系統利用網路、伺服器的功能,讓同類生產線輕鬆共用一台測量機器,節省空間及成本。

DFI 專精工業電腦,提供各種尺寸的嵌入式系統、I/O 組合及效能程度,為各式產業量身打造,不論是在單一系統上安裝多個感測器,讓系統能同時驅動設備及感測器外,或是讓多條生產線共用一台測量機器,都能配合企業的特定需求。DFI 與 iMRC 攜手合作,承諾協助您實現自動化生產目標、減少錯誤成本,並向下一波的工業 4.0 浪潮向前邁進。