EC70A-SU

With the rise of consumer awareness, people are paying more attention to the quality and safety of the products they eat every day. In recent years, regardless of newspapers and magazines, TV reports, talk shows, and Internet public opinion, food safety has often focused on widespread reports and heated discussions.

Food manufacturing usually involves mechanical processing steps, such as shredding or slicing, performed by machines with moving metal parts such as blades. Over time, these parts wear down, leading to small metal fragments in the food production line. Therefore, food processing will be tested for metal contaminants before the final processing stage. For this reason, the application of metal detectors in food processing has become a necessary monitoring device for Hazard Analysis Critical Control Point (HACCP). It's essential to prevent the raw materials in food from being mixed with foreign objects due to improper methods or unavoidable factors in the subsequent processing process because they may harm consumers' bodies and even endanger their lives. At present, the food industry generally uses X-ray analyzers as part of the HACCP’sforeign body inspection and control program, to ensure strict food safety.

When the X-ray analyzer is in operation, it will cause high-frequency vibrations due to conveying various foods on the conveying rollers. The controller computer must have a robust shock-proof capability because it is being installed in a relatively narrow and small space, so there are more stringent requirements for system heat dissipation and power consumption. Customers of the X-ray detectors need a fanless and on-board memory with enough performance to run the self-developed test software such as unique masking function and primitive merging algorithm, which can effectively detect various metal sizes in non-metallic foreign bodies.

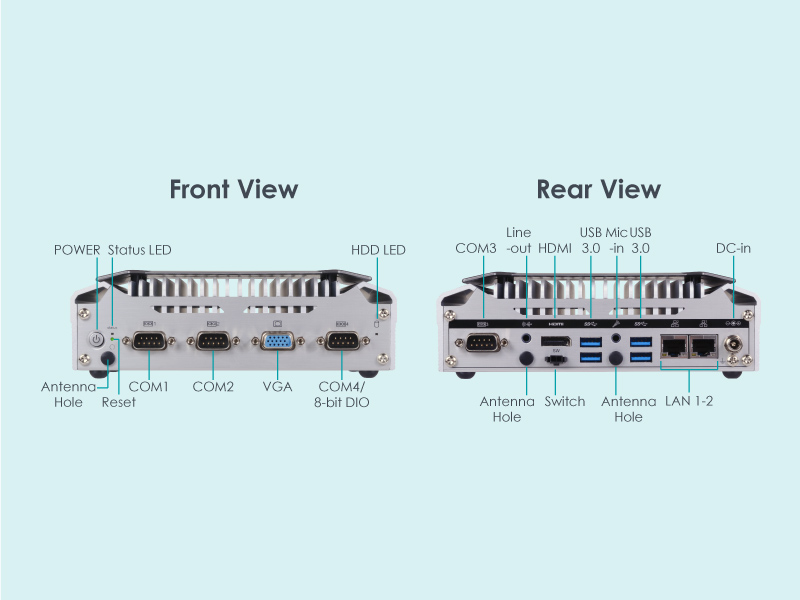

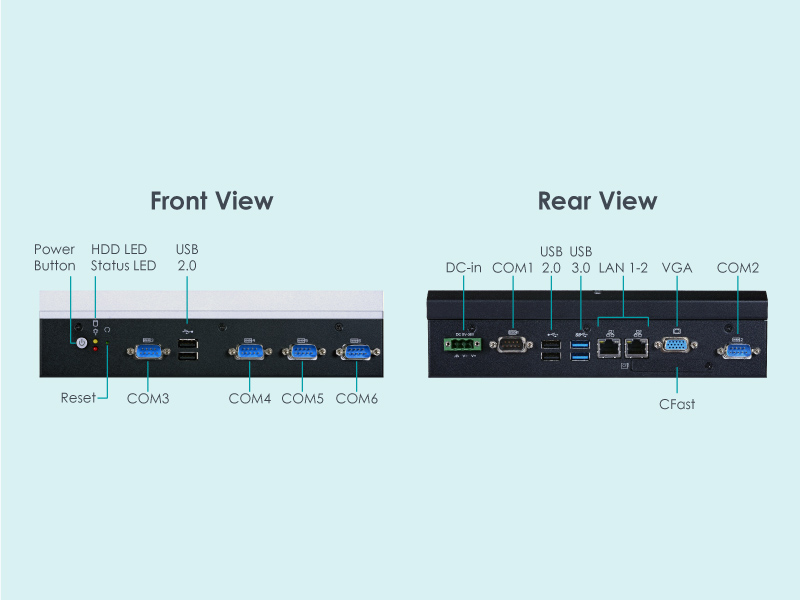

Customers require perfect I/O expandability, 2 RS-232, 1 RS-485, 1 USB, 1 Ethernet, 1 DVI, or VGA to connect peripheral equipment such as PLC, inverter, and vision cameras.

EC70A-SU provides customers with high-efficiency and on-board memory to overcome the high-frequency vibration during equipment operation. When equipped with industrial-standard SSDs, it can operate normally in -20 to 60°C, which avoids the negative impact on stability and reliability and reserves the flexibility to upgrade software functions in the future.

,有助於車隊管理員管理駕駛行為、運動感測、急煞車和衝擊偵測.jpg?timestamp=1689918406.42007)