SCARA

SCARA is a particular type of industrial robot with cylindrical coordinates. It generally has 4 degrees of freedom, including translation along the X, Y, and Z directions and rotation around the Z-axis. The SCARA is characterized by small load and fast speed, so it is mainly used in 3C industries such as quick sorting, precision assembly, or the food industry. The traces of SCARA can be seen in wafers, panel handling, circuit board transportation, and insertion and assembly of electronic components in the IC industry. With the high reliability brought by the onboard memory and the multi-port Ethernet that meets customers' needs, DFI EC700-BT3054 assists customers in creating accurate SCARA.

Region: China

Industry: automated production line

Application: SCARA

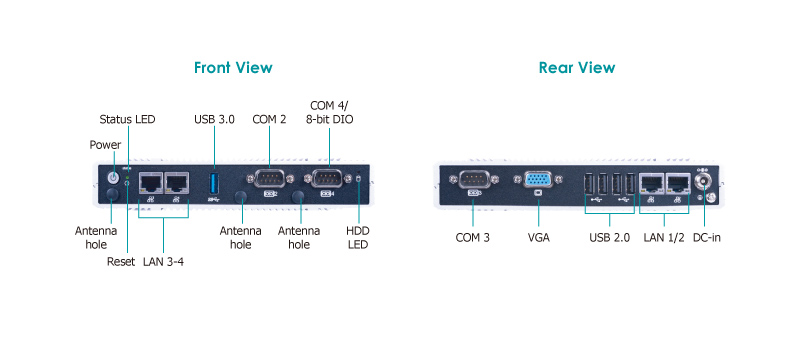

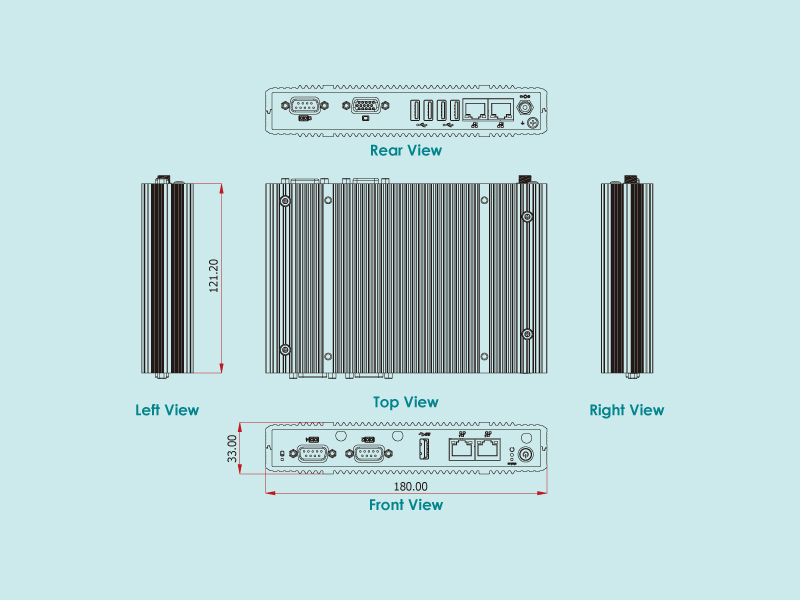

Solution: EC700-BT3054

SCARA (Selective Compliance Assembly Robot Arm or Selective Compliance Articulated Robot Arm) is a specially configured robot arm. It is a new assembly robot concept proposed by a Japanese manufacturer in 1981. A small load characterizes it. On the other hand, the speed is fast, so it is mainly used in fast sorting, precision assembly, other 3C industry, the food industry, and other fields.

The SCARA robot arm has rigidity in the Z-axis direction and can bend in the XY direction. According to the SCARA parallel axis structure, its component is compliant in the X-Y order but rigid in the Z direction, so its name is "selective compliance". This feature has advantages in planar assembly operations, such as inserting a round pin into a round hole.

Another feature of the SCARA is that the joint structure of its two components is similar to a human arm, so there will be the word "articulated" in the name. This feature allows the arm to enter some narrow or restricted areas, and then exit the site by folding. This feature is conducive to moving assembly materials from one closed workstation to another.

Compared with the traditional Cartesian coordinate robot arm, SCARA will respond faster, and the equipment environment will be cleaner. In addition, its single-seat mount requires a smaller footprint, so it adopts a more straightforward and unobstructed installation method. But it also needs more precise software control, such as system control software that supports EtherCAT (Ethernet for Control Automation Technology).

,有助於車隊管理員管理駕駛行為、運動感測、急煞車和衝擊偵測.jpg?timestamp=1689918406.42007)